MIXRAIL - Transload

Request a quote

Summary

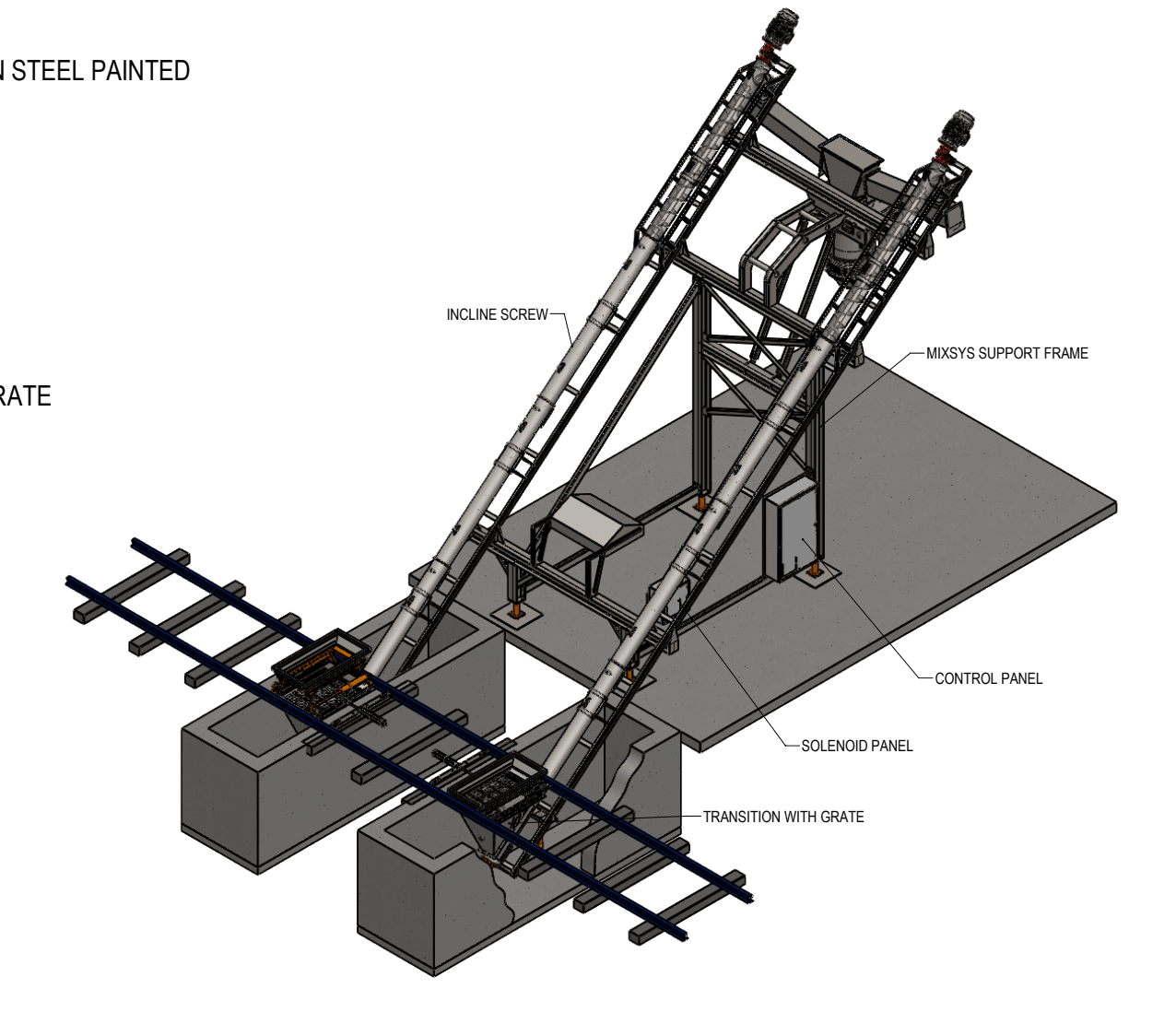

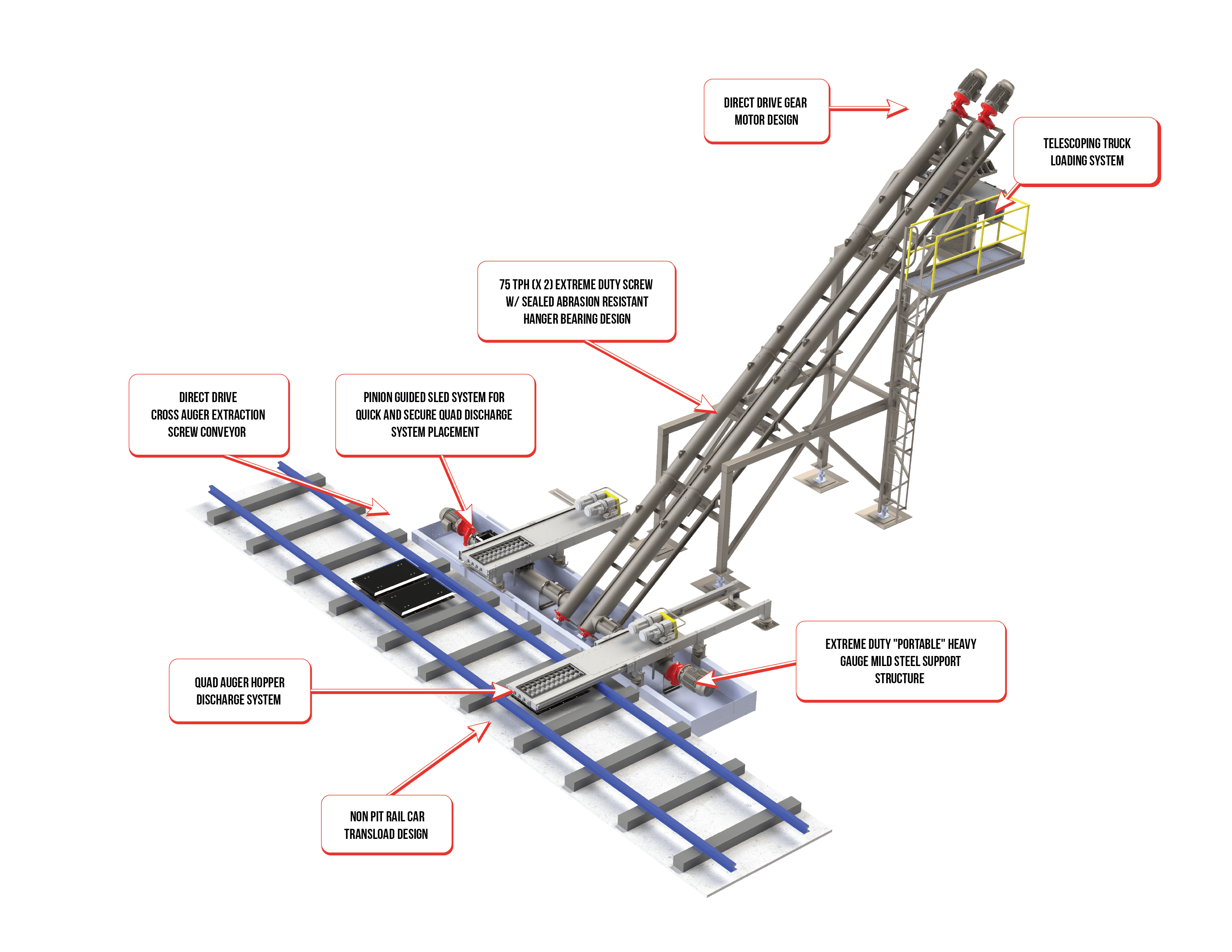

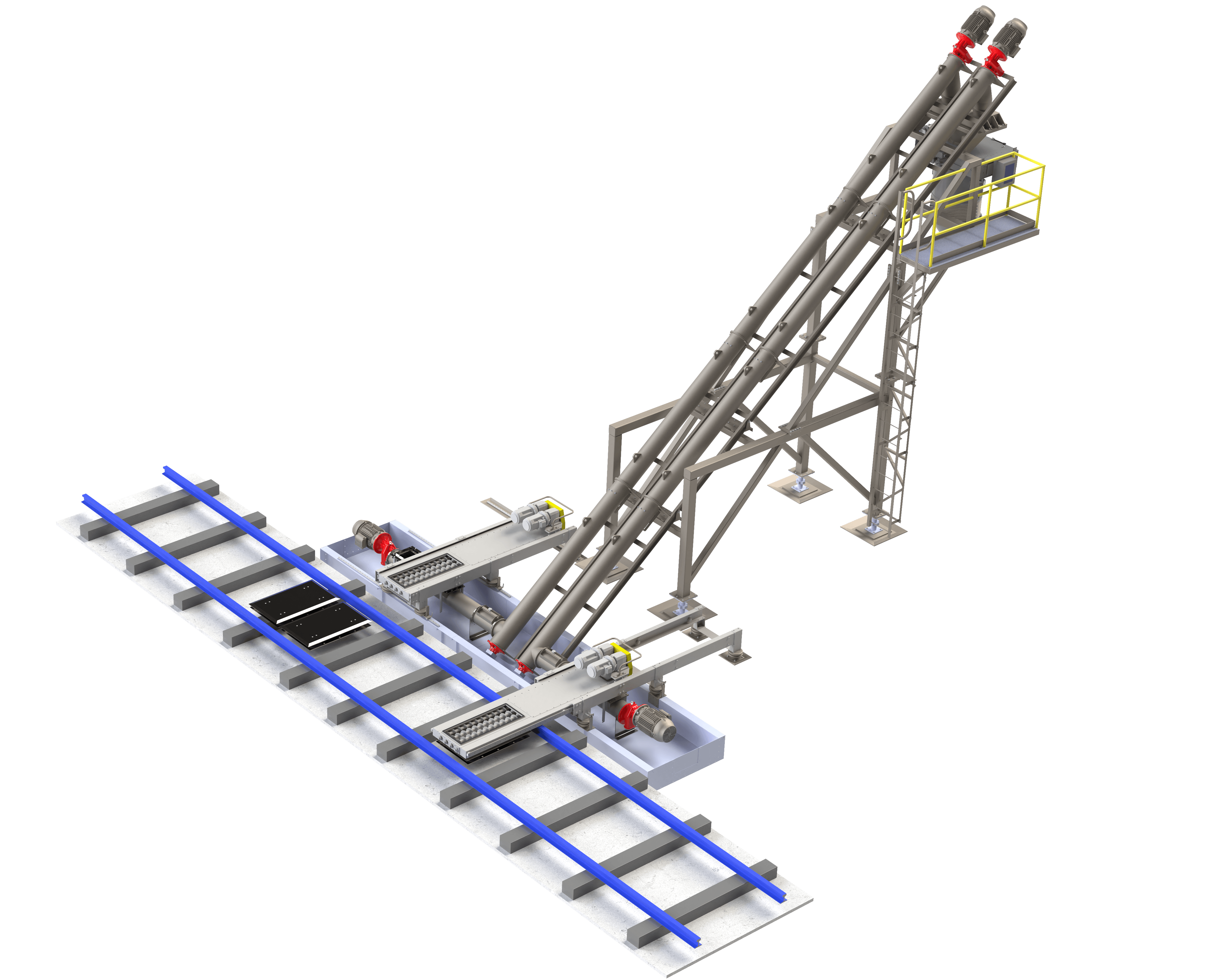

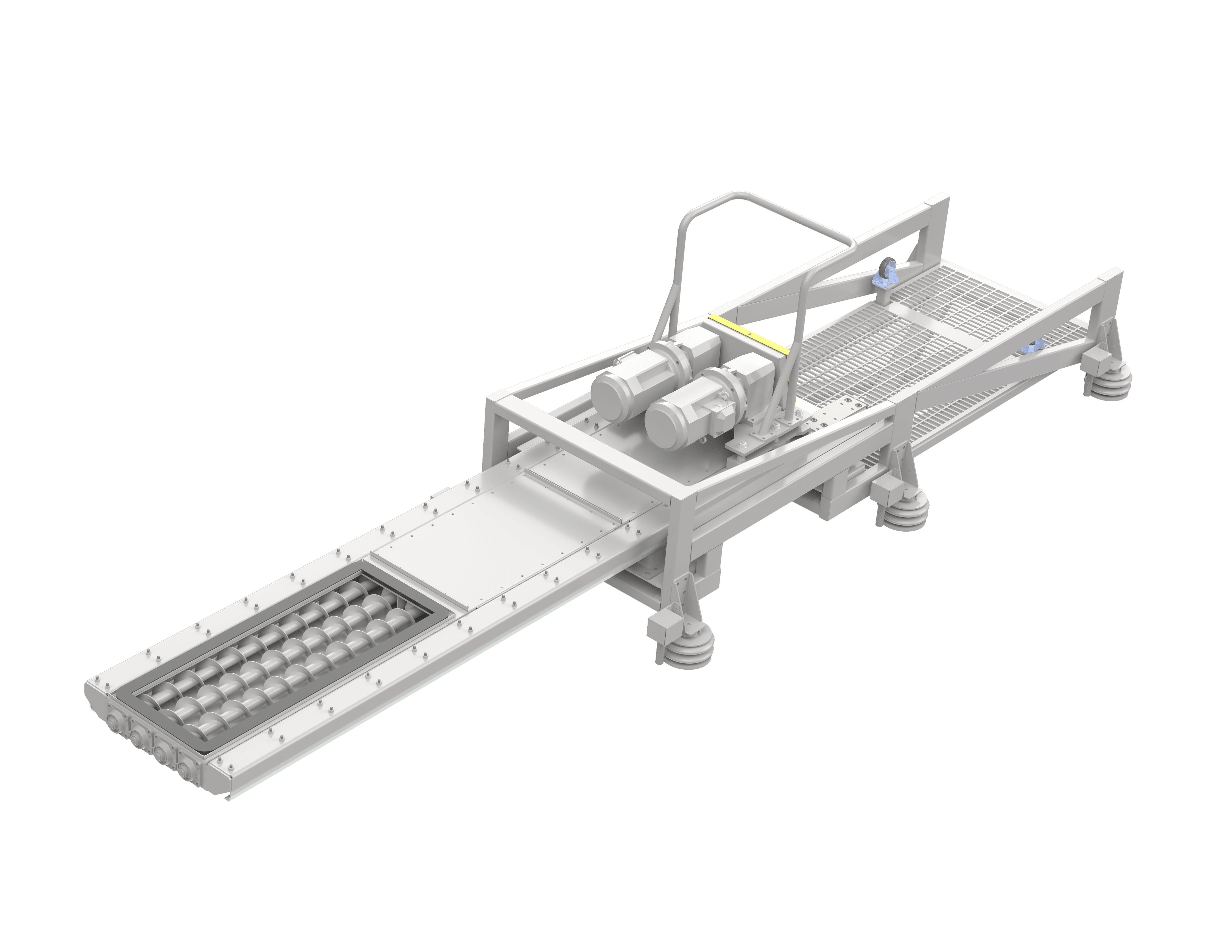

MIXRAILTRANSLOAD represents the next generation of high-capacity hopper rail car unloading systems. It has been engineered to meet the increasing demand for rapid and efficient rail car unloading. This system is ideal for Department of Transportation projects or any application that requires quick setup and flexible relocation to accommodate customer requirements. The MIXRAILTRANSLOAD is a patented solution that does not require special approval or permitting from the Federal Railroad Administration (FRA) and can be relocated as needed.

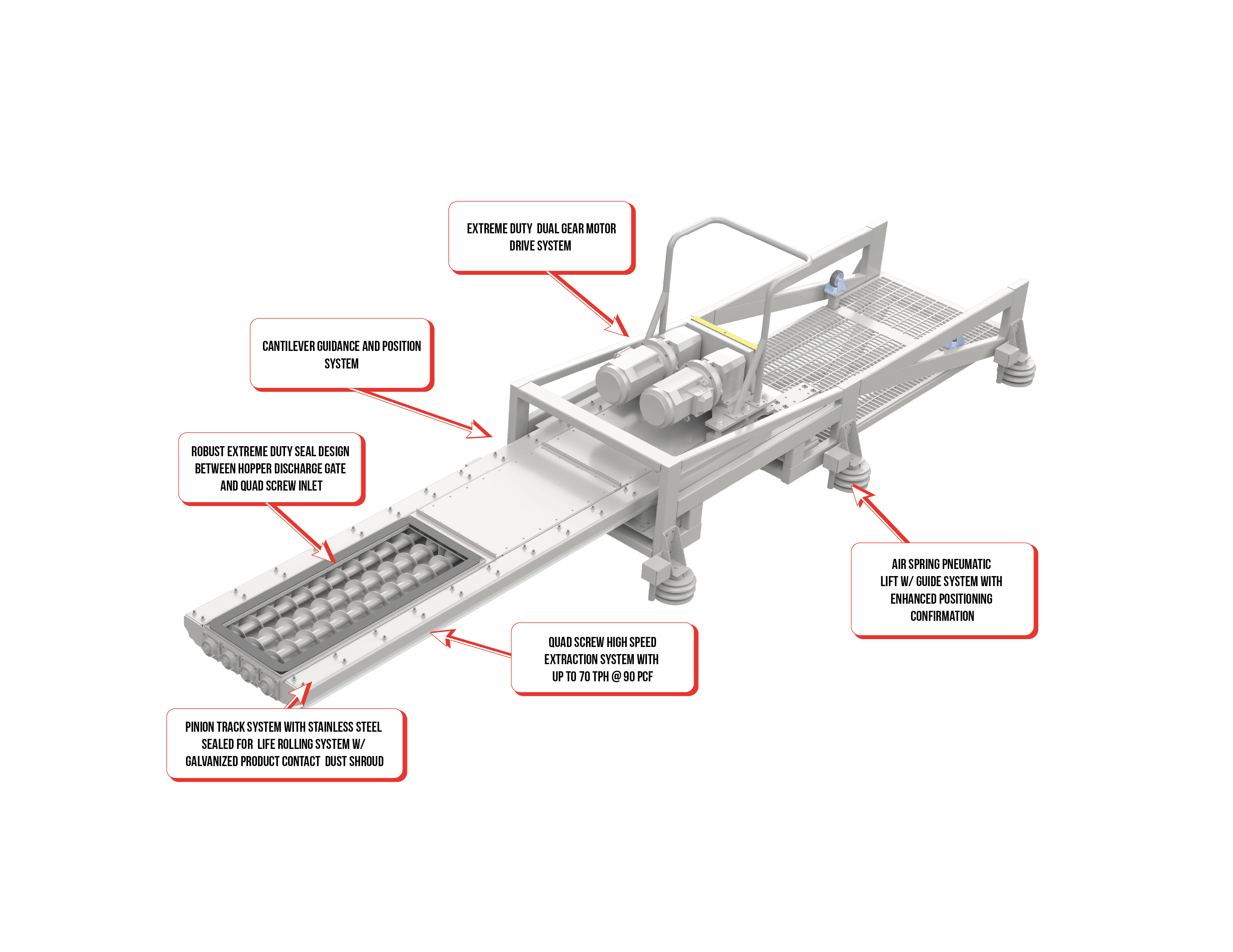

The system consists of a four-screw extraction sled designed to slide between the train rails and the rail car hopper discharge gate. Once in place, a self-leveling, heavy-duty air-bag system elevates the equipment, ensuring a superior seal between the discharge point and the inlet. Additionally, the MIXRAILTRANSLOAD system eliminates the need for a traditional under-track pit design, significantly reducing installation costs and improving maintenance accessibility.

Benefits

- High-Capacity Rail Car Unloading, up to 150 tons per hour

- Patented between Track and rail hopper sled design

- Semi-mobile allowing relocation

- Does not require train tracks pit installation, reducing cost

- Auto Bag Lift Seal System w/ Position Sensor for Clean discharge from Train Hopper.

- Adaptable for direct tanker filling or pneumatic pressure or vacuum system to offload to storage silos.

- Adaptable across all industries from Cement to Flour

Features

Customized Design

- Transload to bulk pneumatic tanker trucks

- Screw Pump Extreme Dusty Pneumatic Conveying to Bulk Storage

- Vacuum Push Pull System to Bulk Storage

- Abrasion Resistant Design for Cement, CaCo2, Fly ash, etc

- Food Grade Design Available

- Under Rail Pit Design Also Available for Transload to Pneumatic Bulk Tanker trucks or bulk storage

Images

MIXRAIL - Transload