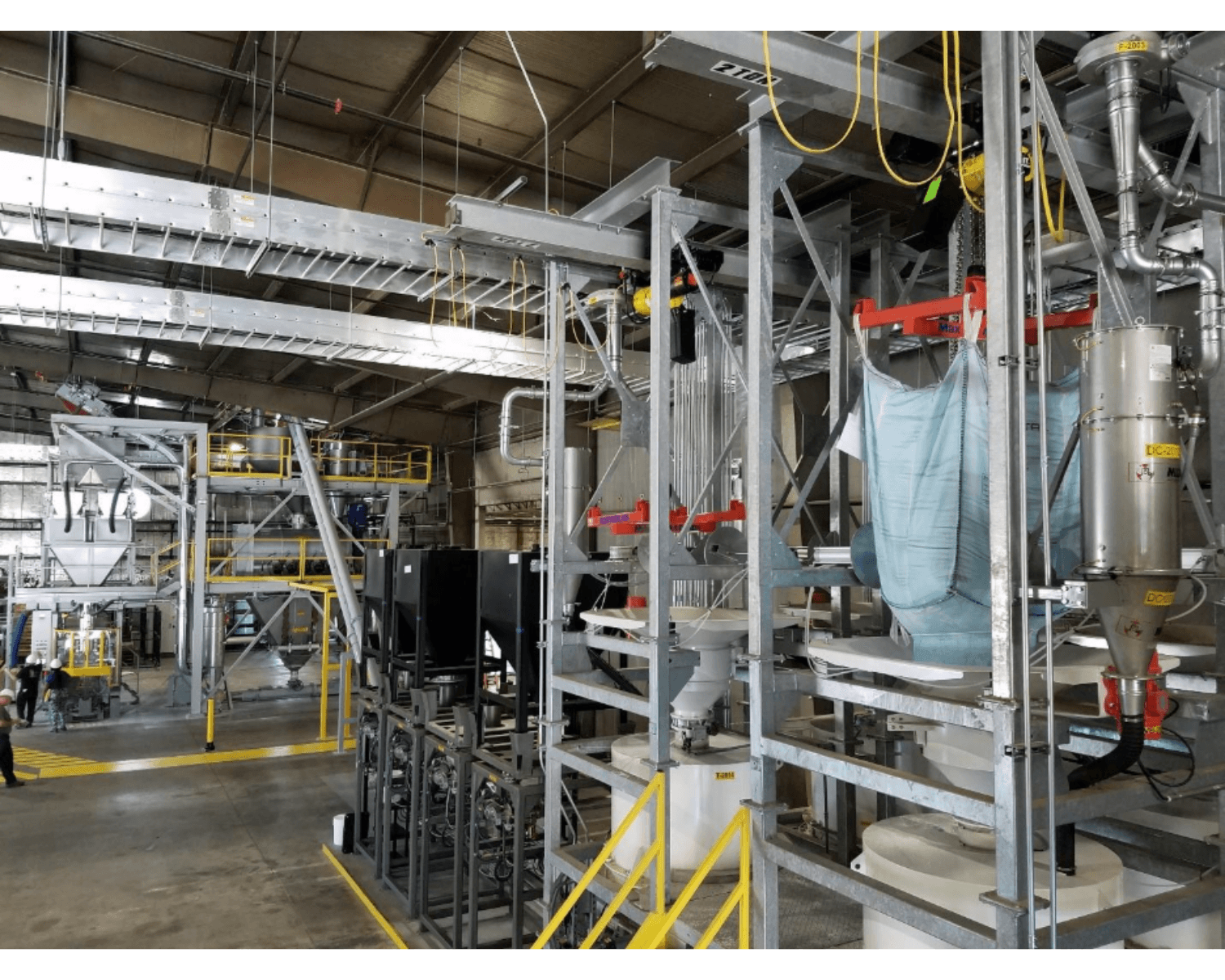

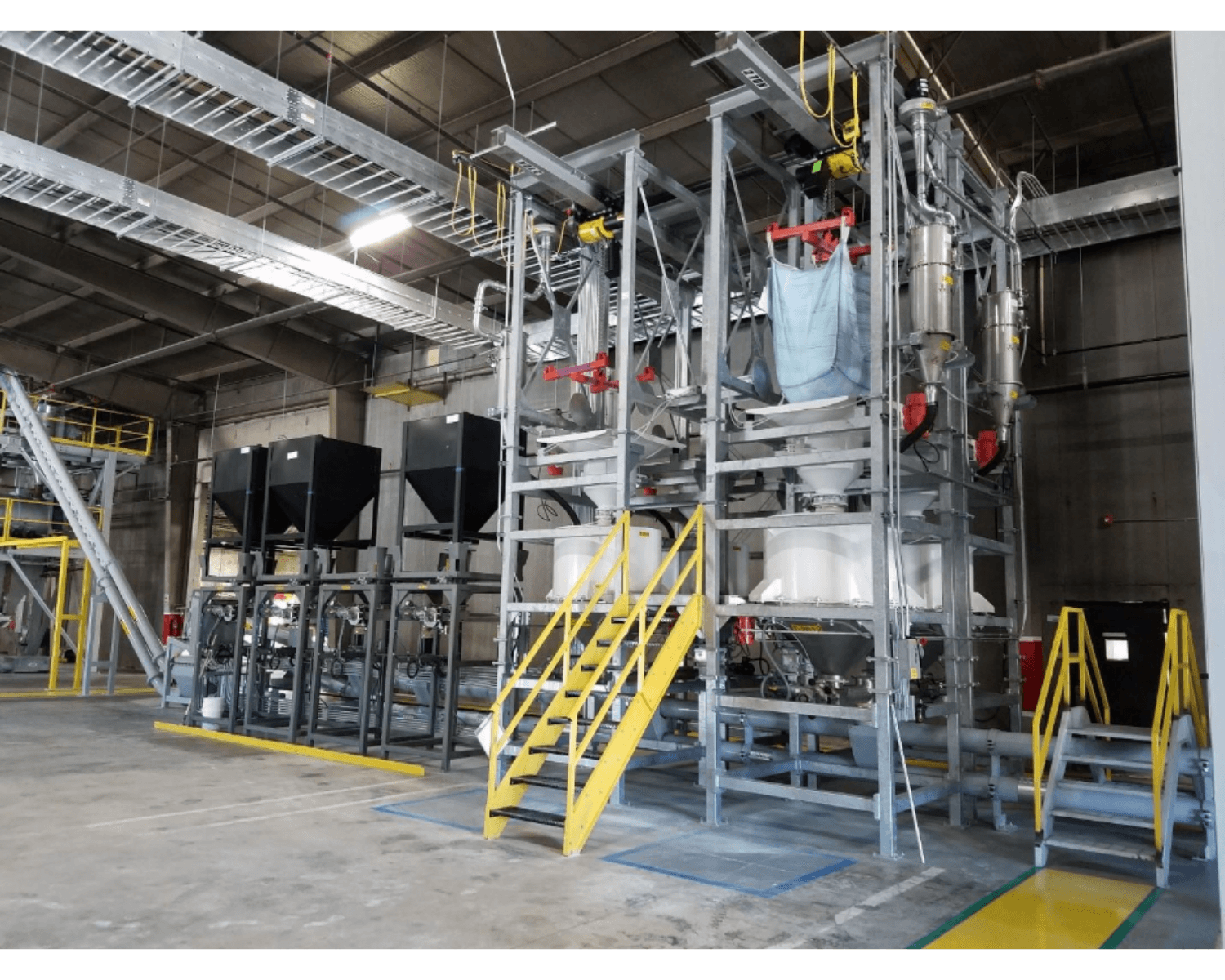

Smart Ingredient System (Modular Tote Ingredient Dosing System)

The MIXSYS Smart Ingredient System provides advanced control and efficiency in industrial ingredient handling for improved manufacturing processes.

Request a quote

Summary

The MIXSYS Smart Ingredient System revolutionizes ingredient handling in industrial processes by offering a sophisticated arrangement of distribution handlers, all seamlessly linked to a central control panel. This innovative system provides precise control over ingredient distribution across various stages of production, ensuring optimal efficiency and accuracy in dosing.

Key features include modular design, allowing flexibility and scalability tailored to specific production needs. A centralized control panel serves as the neural hub, giving comprehensive control over the system with real-time adjustments in ingredient dosing. Adjustable dosing capabilities ensure consistent product quality by allowing precise management of ingredient quantities.

The system integrates smoothly into existing manufacturing processes, enhancing efficiency and minimizing errors. The advantages include improved efficiency and accuracy, flexibility to adapt to changing requirements, and real-time monitoring capabilities that help maintain continuous operation and quick response to any issues.

Overall, the MIXSYS Smart Ingredient System represents a state-of-the-art solution for managing and dosing ingredients in industrial manufacturing settings. It ensures that operations are not only effective but also adaptable, enhancing both productivity and product consistency across all production stages.

Benefits

- Enhanced production efficiency and waste minimization

- Unparalleled accuracy and product quality

- Customizable and expandable design

- Proactive problem-solving with real-time monitoring

- Smooth operations with minimal interruptions

- Raw Material Complete Lot Tote Storage For superior Tracking and Tracing

- Reduced Capital Investment

- Reduction in Required Feeders (Feeders based on maximum ingredients per batch campaign, not amount of raw ingredients)

Features

Modular Design

- Tailored to specific process requirements

- Flexible configuration and scalability

- Supports diverse manufacturing needs

- Raw Ingredients are transloaded into a Modular Mass Flow IBC Tote

Centralized Control

- Comprehensive control from a central panel

- Intuitive interfaces for real-time adjustments

- Monitors and adjusts ingredient dosing parameters

- Integration of SMARTBATCH Controls Logic recipe management with enhanced track and tracing of ingredients from Tote filling through Packaging

Dosing Precision

- Precise control over ingredient quantities

- Enables fine-tuning for each processing unit

- Ensures consistency and accuracy in products

- Batch and Continuous Dosing

- Micro Dosing and Micro Dosing

- Adjustable to various feeders based on product characteristics such as screw feeders, vibrator feeders, belt feeders, etc

- Optional MIXQUICKCLEAN dosing screw

Integrated Management

- Streamlines ingredient handling

- Reduces manual intervention

- Minimizes risk of errors or inconsistencies

- Consistent and accurate recipe management and control

- Complete integrated reporting and management